Sodium Bicarbonate Use in Poultry Feed — 2025 Trends

Sodium bicarbonate (NaHCO₃) continues to gain importance in poultry nutrition, especially as global producers focus on heat-stress management, electrolyte balance, and improved eggshell quality. In 2025, demand for feed-grade sodium bicarbonate is expected to increase across Asia, the Middle East, and Latin America due to rising temperatures and expanding layer and broiler production.

1. Why Sodium Bicarbonate Matters in Poultry Feed

Sodium bicarbonate provides a highly bioavailable source of sodium and acts as a key buffer in poultry diets. Compared with common salt, sodium bicarbonate delivers sodium without chloride, improving electrolyte balance and reducing heat-stress risks during high-temperature seasons.

Key benefits:

Maintainsacid–base balancein birds

Improveseggshell thickness and uniformity

Supportswater and feed intakeduring heat stress

Enhancesoverall performance and FCR

As climate conditions become more extreme, farms increasingly incorporate sodium bicarbonate into broiler and layer diets.

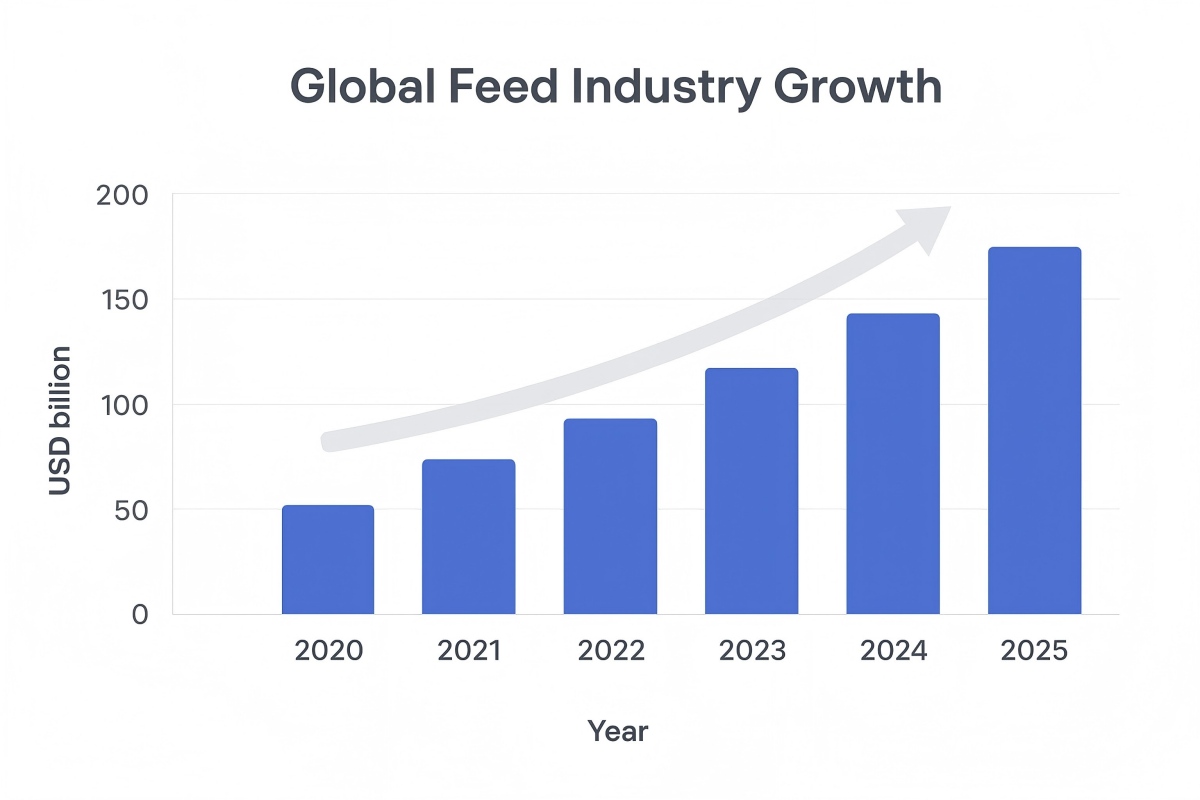

2. 2025 Global Market Trends

• Rising heat stress challenges— Regions such as Southeast Asia, Middle East, and Africa are using more sodium bicarbonate to reduce mortality during hot seasons.

• Growth of large-scale poultry farms— Bigger operations prefer stable, free-flowing NaHCO₃ for automated feed lines.

• Shift toward low-chloride diets— Nutritionists are reformulating to reduce chloride load, making sodium bicarbonate essential.

• Expanding export markets— Many feed mills in India, Indonesia, Malaysia, and Brazil are increasing imports due to strong domestic poultry consumption.

3. Recommended Inclusion Rates

Typical usage levels (for reference only — nutritionists may adjust based on formulation):

Broilers:0.1% – 0.3%

Layers:0.2% – 0.4%

Breeders:0.2% – 0.35%

Sodium bicarbonate can partially or fully replace salt depending on dietary chloride levels.

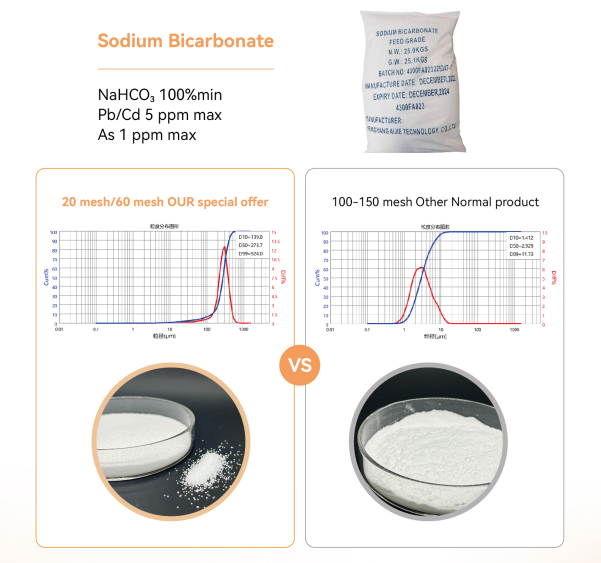

4. Choosing the Right Sodium Bicarbonate in 2025

High-quality feed-grade NaHCO₃ should have:

≥ 99% purity

Low moisture and strong flowability

Uniform particle size (ideal for premix and large feed mills)

Stable performance in storage in humid climates

A consistent product helps ensure accurate batching and prevents caking during transportation.

5. Conclusion

With rising global temperatures and more focus on performance efficiency, sodium bicarbonate will remain a key ingredient in poultry feed in 2025. Its role in maintaining electrolyte balance, reducing heat stress, and improving eggshell quality makes it a reliable and cost-effective choice for feed mills and poultry farms worldwide.

Internal Links

Sodium Bicarbonate – Feed Grade NaHCO₃ Sodium Bicarbonate

Copper Sulphate – Essential Mineral for Feed Copper Sulphate

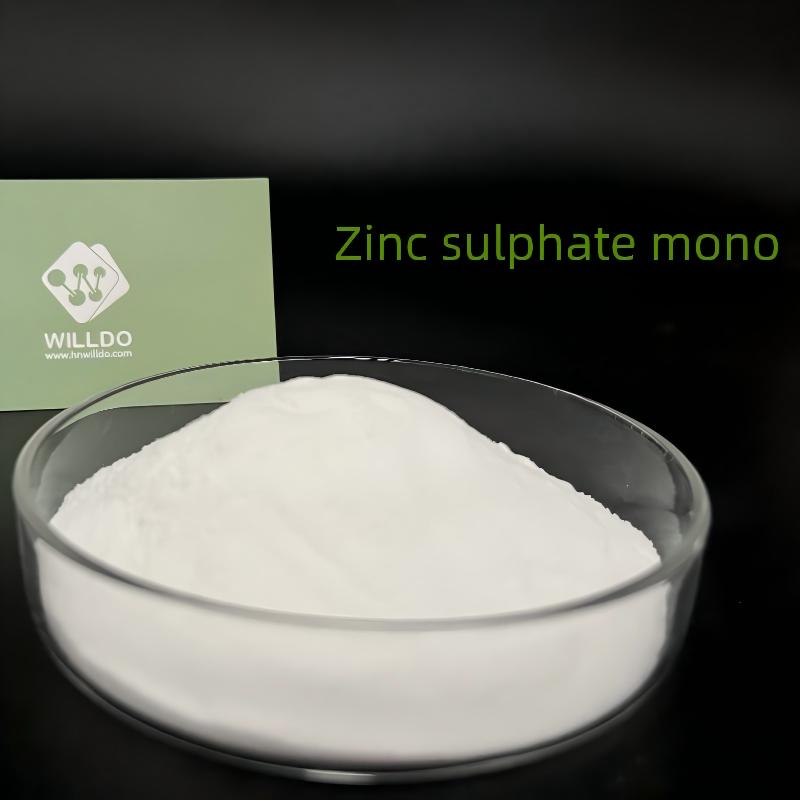

Zinc Sulphate Monohydrate – High-Bioavailability Zn Source Zinc sulphate mono