Why Manganese Sulphate Prices Remain Stable in 2025 — And What It Means for Global Feed Producers

Introduction

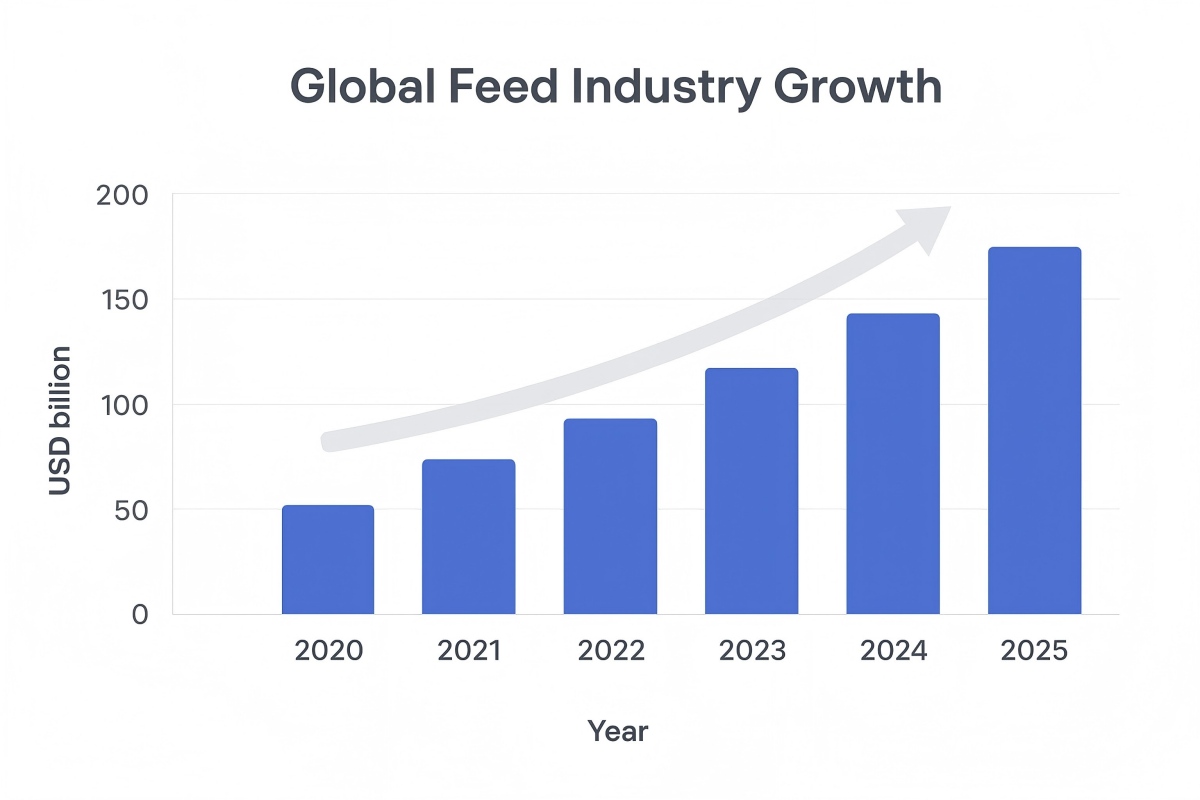

In the first half of 2025, many inorganic mineral additives have seen significant market fluctuations, especially copper-based products. While copper sulphate prices continue to rise due to cost pressure from upstream copper smelting and tight spot supply, manganese sulphate has taken a different path.

Its price remains stable, predictable, and cost-effective — making it the most reliable trace mineral for feed producers in 2025.

This stability is now influencing major purchasing decisions in the feed industry.

1. Why Manganese Sulphate Prices Stay Stable in 2025

1.1 Upstream raw materials are more predictable

Unlike copper, whose smelting cost is heavily linked to global commodity speculation, themanganese ore supply chain remains stable, with wide upstream availability and no major disruptions in mining regions.

1.2 Production technology is mature and scalable

Manganese sulphate monohydrate is produced through established processes with consistent capacity.

Plants can operate at stable output without the major shutdown cycles or maintenance interruptions seen in copper refineries.

1.3 Demand is strong but not volatile

Feed-grade MnSO₄ is widely used globally, but its demand curve is smooth.

This steady consumption allows producers to maintain long-term contracts and stable pricing.

1.4 No speculative price spikes

Copper markets are sensitive to financial speculation, causing sudden price surges.

Manganese, on the other hand,does not face such investment-driven volatility, keeping MnSO₄ prices stable throughout the year.

2. What This Means for Feed Premix & Feed Manufacturers

2.1 Easier long-term cost planning

Stable raw material prices allow premix factories and integrators to plan procurement cycles more accurately.

This is especially important when feed mills face tight margins.

2.2 Lower risk in monthly or quarterly purchasing

For copper sulphate, buyers often need to update prices weekly — sometimes daily.

In contrast,manganese sulphate offers predictable monthly or quarterly quotations, reducing the stress on purchasing teams.

2.3 Consistent quality supports feed formulation stability

High-purity feed-grade MnSO₄ (Mn ≥31%) provides reliable bioavailability for poultry, swine, and ruminant feeds.

Stable quality = stable premix formulations.

2.4 A safer choice for regions with strict impurity limits

Feed safety standards are tightening in many markets, including the EU, Canada, and Southeast Asia.

Manganese sulphate typically holds:

Low heavy metal content

Good flowability

Low moisture

Light pink appearance

These attributes make MnSO₄ a preferred mineral source when producing high-value feed.

3. A Practical Buying Trend for 2025: Switching From Copper Sulphate to MnSO₄ for Certain Applications

In many countries, buyers are temporarily reducing copper sulphate stocking volumes because of:

Inflated market price

Importers’ difficulty locking stable supply

Unpredictable shipment timing

As a result,many buyers are increasing their purchases of zinc sulphate and manganese sulphate, securing the minerals where stable supply still exists.

For premix factories, MnSO₄ is now one of the most “budget-friendly and stable trace minerals” in their formula.

4. What Feed Producers Should Do in 2025

4.1 Lock a stable supplier before Q3

The market is expected to tighten in the second half of the year as more buyers switch away from copper-based options.

4.2 Build 2–3 months of inventory

A small buffer helps stabilize production and protects against freight fluctuations.

4.3 Consolidate shipments to reduce freight cost

Many suppliers now support mixed loads:

Manganese sulphate

Zinc sulphate

Sodium bicarbonate

Ferrous sulphate

This reduces shipping fees and improves procurement efficiency.

Conclusion

With copper sulphate prices fluctuating sharply,manganese sulphate stands out in 2025 as one of the most stable, cost-effective, and reliable minerals for the feed industry.

Its predictable pricing, strong supply chain, and high-quality feed-grade standards make it the smart choice for premix factories, feed mills, and distributors worldwide.

For buyers looking to secure a consistent supply in 2025, manganese sulphate is not only a safer option — it’s a strategic one.